Effective protection of power supply cables and people in industry

In the automotive sector, OBO concentrates mainly on system construction and conveyor technology. Our focus is on chassis construction, that is the wiring of machines or systems along the production lines. The electrical installation in chassis construction covers 75% of the overall installation. Powerful protection against footfall, dust and many other loads is essential for reliably supplying the systems with power and data. To meet these requirements, OBO offers the BKRS walkable cable tray system. The system is designed for the highest loads, which frequently occur in the vicinity of machines and automated production systems with robotic elements.

Quick start

The BKRS system offers the automotive industry these benefits

- The BKRS system is already appreciated by numerous giants of the automotive industry and has been approved in the factory standards of BMW Group, Volkswagen AG, Volvo Car Corporations, Jaguar Land Rover Ltd., Mercedes-Benz Group and Ford

- The dimensions and materials mean that they satisfy the guidelines and requirements of numerous other industries.

- UL-certified NEMA VE1

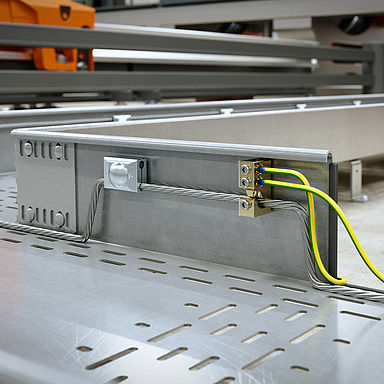

- Effective protection for energy, power and data supply in automated production lines and system construction applications

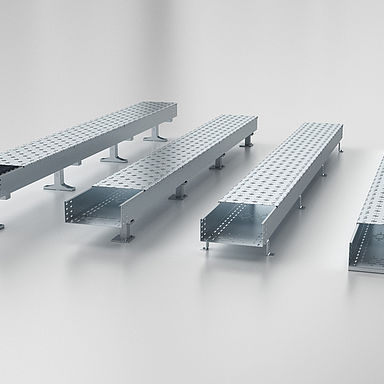

- Available with the side heights 100 and 110 mm

- With six widths between 100 and 600 mm available, there is a suitable cable tray system for every possible application

A system only a complete provider can deliver:

These product features provide stability in the automotive industry:

Downloads

FAQ

- What exactly are walkable cable tray systems?

Walkable cable tray systems are robust, modular support systems for reliable routing and distribution of power and data lines in industrial environments. They are designed so that people can walk on them – ideal for maintenance, inspection and assembly in production systems.

- What applications are OBO cable tray systems used for in the automotive industry?

Primarily, OBO cable tray systems are used in the automotive industry in production and assembly halls, test stands, battery assembly lines and in chassis and painting plants. They enable efficient, reliable and flexible cable routing in areas with high mechanical and thermal requirements.

- What benefits are offered by OBO walkable cable trays?

The BKRS system from OBO stands for a maximum load-bearing capacity and stability. It enables fast access for maintenance work and, thanks to its modular design, is suitable for flexible adjustments. The corrosion-resistant material makes it long-lasting. The BKRS system is compatible with existing industrial plants and features a patented cover system and reliable slip protection.

- Can the systems be customised?

Yes, OBO develops customer-specific solutions – from initial planning to the final delivery. Dimensions, load capacity, surface coating and accessories can be tailored to the customer’s individual requirements.

- Do OBO cable tray systems correspond to defined standards?

Yes, all systems meet the applicable European standards, in particular DIN EN 61537 and other industry-specific specifications of the automotive industry.

- What sustainability aspects does OBO take into account in production?

We rely on resource-efficient production processes, recycling of metals and regional suppliers to minimise transportation routes and carbon emissions.

- What automotive manufacturers does OBO already work with?

OBO has supplied leading OEMs and suppliers from the automotive industry for many years. On request, we would be happy to provide you with reference customers and example projects.