Implementing equipotential bonding with the BKRS system

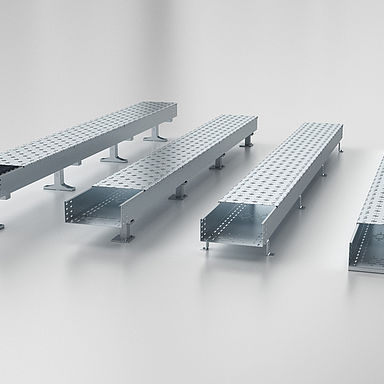

The BKRS walkable cable tray system can be quickly and easily included in the equipotential bonding. Four different options are available for this, making it possible to select based on installation conditions and environment.

Quick start

The different options for inclusion in equipotential bonding at a glance

Option 1: End-to-end equipotential bonding in the cable tray profile

A continuous tin-plated copper cable is guided directly in the cable tray profile and fixed using the clamp spring. Installation is easy, done without tools or any additional drill holes – ideal for quick and clean integration into existing systems. Contacting can be established quickly, as the copper cable is inserted directly into the clamping spring.

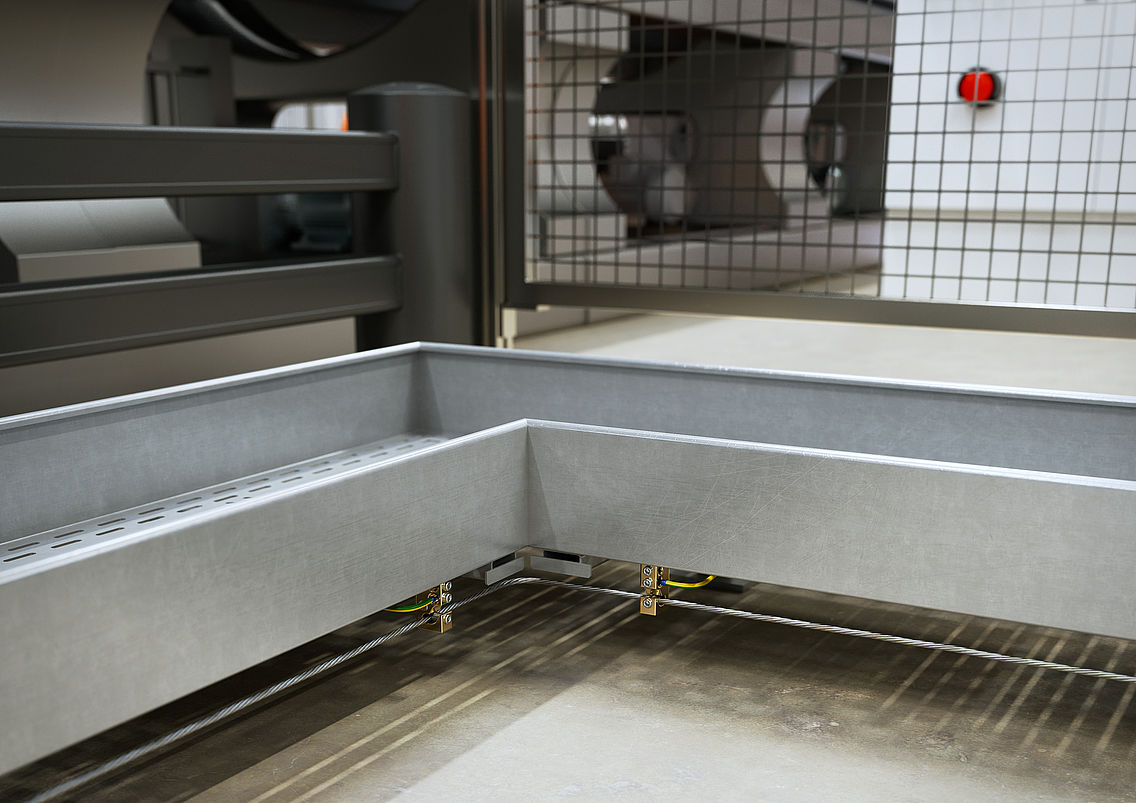

Option 2: Equipotential bonding under the cable tray

In this system, the conductor cable is guided under the cable tray using connection terminals. Tin-plated copper cables in accordance with DIN VDE 0295 Class 2, multi-wire and tin-plated conductor cables according to DIN VDE 0295 Class 5, fine-wire and pair-stranded, from 16 mm2 to 35 mm2 can be used. Fastening is done using the OBO connection terminal.

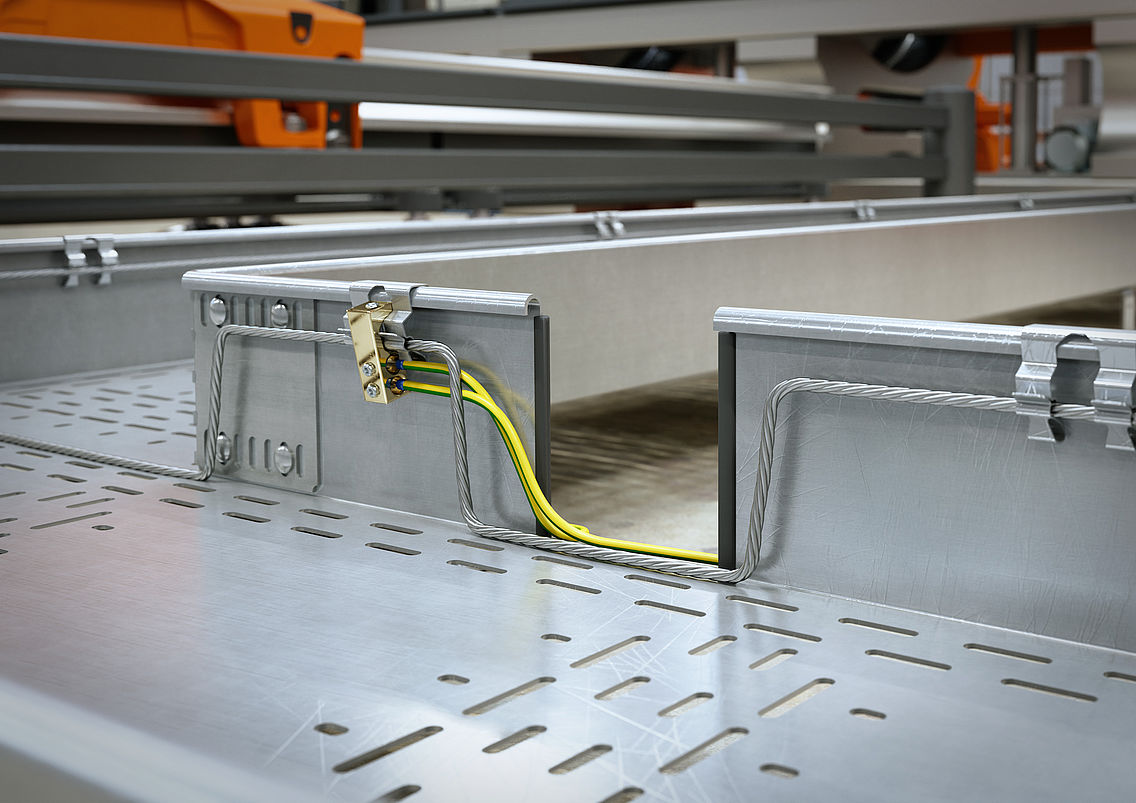

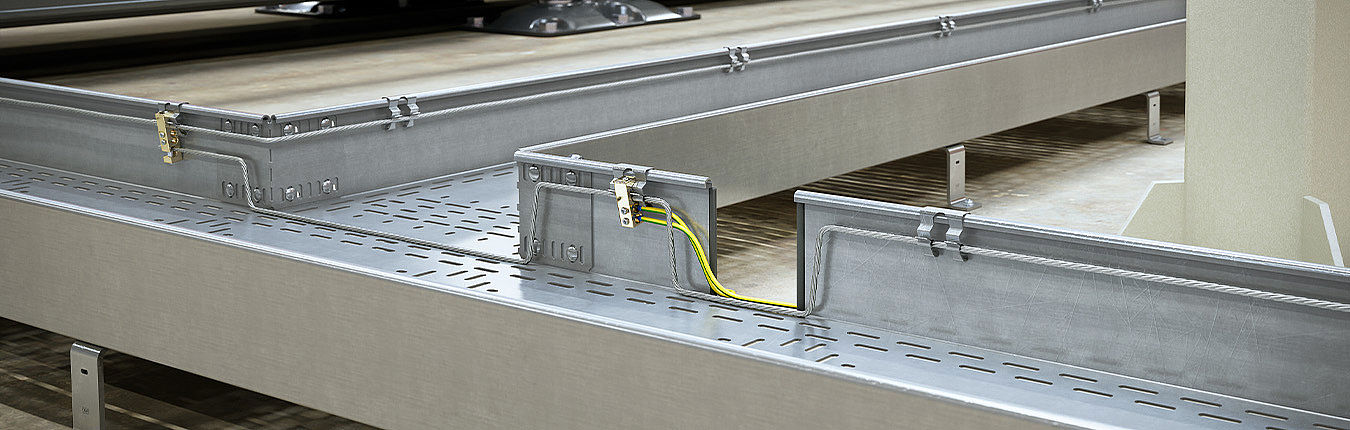

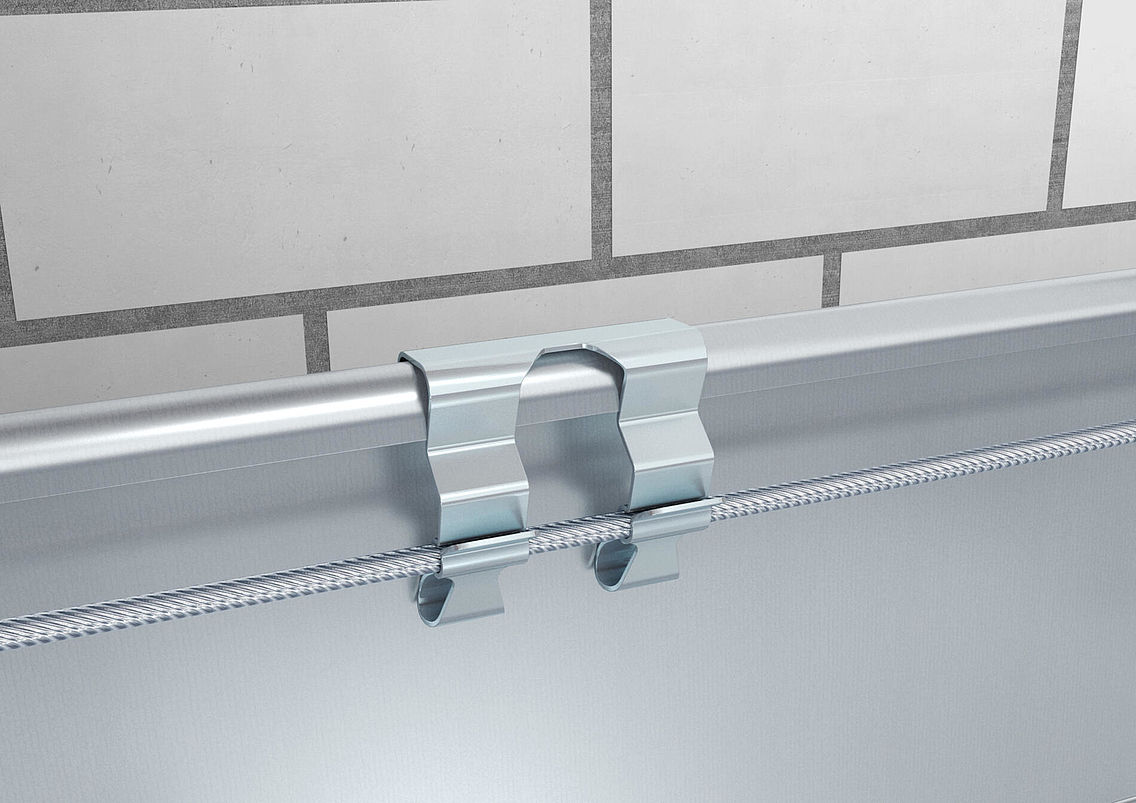

Option 3: Equipotential bonding with central exit

Equipotential bonding is achieved using a 35 mm2 copper cable, tin-plated in accordance with DIN VDE 0295 Class 2. It is routed continuously using parallel connectors. The connection terminal can be mounted anywhere and connected to the conductor cable. It has 2 exits for round conductors up to 35 mm2.

Option 4: Equipotential bonding with flexible branch structure

This system enables structured earthing with flexible branches. Copper cables are supported using special connection terminals and guided via round conductors. The ideal solution for branched earthing grids with different cable cross-sections.