The new way to plan underfloor systems

OBO Construct for underfloor systems, version 3.0

Following on from OBO Construct for earthing systems, the first generation of which was developed directly using a new technology, the configurator for underfloor systems is now also moving to the new OBO Construct platform, which can be found on our website under the menu item Service.

OBO Construct for underfloor systems had already assisted in the past with creating plans. However, technology has continued to evolve, in particular our digital usage behaviour. User-friendly interfaces, dynamic filter functions and fast loading times set new standards in the development of web applications.

Even easier operation simplifies your planning

OBO's focus during the revision of the existing program was on creating intuitive and transparent planning software. The configuration of the underfloor system has been divided into independent subsections. This enables fast planning of individual applications, such as retrofitting. At the same time, the same planning processes take into account the requirements of multifaceted applications and more complex project conditions.

Precisely matched

Users can start configuring their underfloor system at one of two points, depending on their requirements, by selecting devices or device installation units.

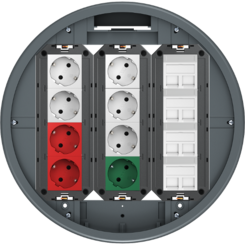

The floor boxes can be assembled using individually defined floor parameters – for cavity and raised floors, as well as for screed-covered duct systems. Equipping the device installation units with sockets and data and media technology requires just a few clicks in this new generation of the underfloor configurator.

The heart of the configurator is the clearly structured planning overview. Here, users divide their buildings into usage units and rooms. Once configured, floor boxes are saved as a template for the entire project and can thus be used multiple times. The software automatically checks in the background whether a floor box is compatible with a room. The appropriate inspection covers can be selected directly from an existing room with the same floor parameters.

Additional functions streamline planning

Other additional functions, such as copying usage units and rooms, reduce the amount of planning required for building sections with a similar floor structure.

The ducting planner calculates the ducting routes, including any necessary accessories. This allows the duct selection to be recorded independently and quickly. The appropriate heights and widths of duct branches between two floor boxes can be filtered using multiple selection.

By further developing UFS Construct, OBO Bettermann is pursuing its goal of providing a useful supplement to existing planning methods and systems with its configurators. Using the programmes means no duplication of planning work for the user, as existing and planned project parameters can be quickly and simply transferred.

Using OBO Construct for underfloor systems means selecting the necessary accessories, e.g. appropriate height-adjustment units depending on the floor height, is simple. The configurator then only needs to determine the most suitable system, including all the necessary components, saving time and reducing the risk of incorrect planning.