The welded cable ladders from OBO: Highly-resistant connection, extremely high load capacity

For many years now, electrical installation engineers around the world have used the welded Cable ladders from OBO, which are used in millions of industrial systems around the world. Each individual component is well thought-out, robust and easy to mount.

Pure cable ladder competence from OBO

OBO has optimised the welded cable ladder for industrial use. Thanks to their special design and intelligent rungs, they can offer a wide range of mounting benefits. The range of materials is also not forgotten: The cable ladders are available in strip-galvanised and hot-dip galvanised versions, along with rustproof A2 and A4 stainless steels and a powder-coated version.

The benefits of the welded cable ladders at a glance

- High resistance: The rungs of the cable ladders are welded to the lower flange. The firmly bonded connection is highly resistant and can also withstand large loads. The interlocking connection of the rung and lower flange guarantees an optimum application of force.

- Practical cover: In a horizontal installation, an attached cover protects the cables against soiling and dust.

- Added installation space: A further advantage is produced by the special position of the rung: The welding of the rung with the lower flange gives the cable ladder added installation space for cables.

- Tested: Stability and reliable corrosion protection, even at both welding points: Both properties were tested in the BET Test Centre. Our welded cable ladders withstood the salt spray and load tests with ease.

Innovative rung

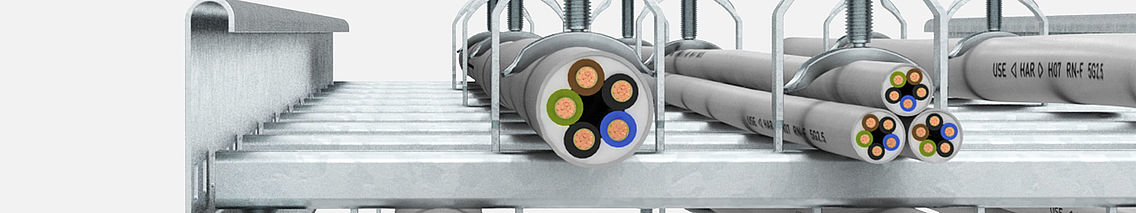

The innovative and patented rung is the hallmark of the OBO welded cable ladder. It is used in the entire cable ladder system, up to a width of 600 mm. Its well-thought-out hole pattern is tailor-made for the requirements of various industrial installations. The special feature: The rungs can be filled on both sides using the matching clamp clips. This allows optimum exploitation of the installation space and flexible equipment of the conductors. This means that smaller and thus lower-cost conductor widths are often sufficient during mounting.

Perfectly matched wall mounting

The welded cable ladder stands out not only through the horizontal mounting, but primarily due to the practical installation benefits in direct wall mounting. During wall mounting, the well-thought-out construction of the cable ladders ensures a spacing of around 5 mm between the rung and the wall, creating free space during the installation. As a suitable accompaniment, through a wide range of variants and sizes, OBO can offer the right Clamp clip for every installation situation. Here is an example: In areas with special requirements, such as an industrial environment, clamp clips with a metal trough can be used.

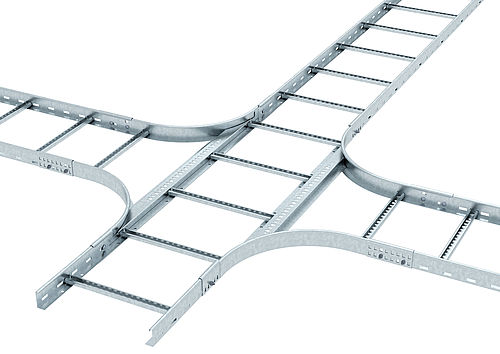

Perfectly matched: The fittings

The fittings of the cable ladder system are the logical addition to the section material. They are also manufactured with welded rungs and in the materials and surfaces of the cable ladders.

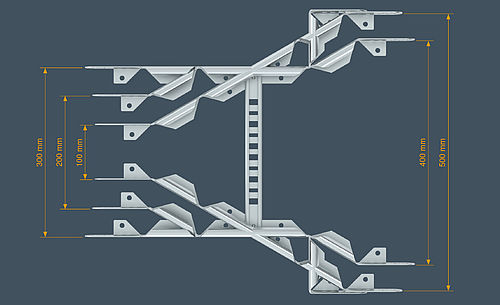

- Simple handling: An optimised standard radius of 300 mm instead of the previous 490 mm makes the fittings more compact and thus easier to handle.

- Continuous perforation: The fittings can also be assigned on both sides thanks to the innovative rung. The continuous perforation allows the use of a wide range of OBO clamp clips.

- One for all – the Multifunctional connector: With the OBO component, cable ladders can be interconnected simply, thus offering flexible implementation of changes in form and direction. Its side rails can be adapted to any angle and installation situation, meaning that both symmetrical and asymmetrical reductions are possible.

OBO cable ladders stand for tested safety

In our in-house BET Test Centre, OBO simulates loads that the cable ladder systems must withstand continuously. We determine the maximum load capacity and carrying capacity of the system, as well as its resistance to corrosion. Standardised testing of the EMC properties can be proven using test reports. This means that, as a systems provider, OBO places paramount importance on safety. In the KTS testing system, OBO has constructed a special system for testing cable support systems. It is continuously being developed further to adapt it to the latest requirements, meaning that it can offer comprehensive testing options. Here, for example, the tests prescribed by DIN EN 61537 can be carried out. This represents a safe working load, which proves the reliable stability of the systems.