Bolt tie BZ3 – stable and safe

Holds things tight – right when it matters

The bolt tie BZ3 complements the OBO portfolio in the area of industrial installations and creates a connection between cable support and fastening systems. The bolt redefines the effectiveness and flexibility of mechanical expansion anchors. The BZ3, with European Technical Approval, offers a very high load-bearing capacity when used in cracked and non-cracked concrete. Already at the dimensioning stage, it offers flexibility with regards to anchoring depth, edge and centre distances.

All benefits of the BZ3 at a glance

- European Technical Approval ETA-19/0619 for application in cracked and non-cracked concrete

- Earthquake-proof: From an anchoring depth of 40 mm it is approved for seismic stress of performance categories C1 and C2

- Shock approval by the Federal Office for Civil Protection, Switzerland

- Bolt tie BZ3 with the highest approved loads and variable anchoring depth

- Highest flexibility for the optimal adaption to the mounting situation

- The tightening torque is achieved in fewer turns

- Coloured marking of the minimum anchoring depth means time is saved when mounting

- Low minimum anchoring depths

Application areas for the bolt tie BZ3

The bolt tie BZ3 is used typically when fastening facades, wood constructions, bannisters, loading ramps, shelves or also cable support systems, such as suspended supports or wall and support brackets, to concrete.

The bolt tie BZ3, made from electrogalvanised carbon steel or stainless steel, can be used for all safety-relevant fastenings in cracked and non-cracked concrete. The electrogalvanised version is suitable for application in dry indoor areas and the stainless steel version can also be used in more aggressive environmental conditions.

High loads with variable depths

The bolt tie BZ3 combines the highest approved tensile and transverse loads with variable anchoring depths. It is designed in such a way that it allows for higher loads than comparable models. By setting it deeper, these loads can be increased further and the bearing capacity of the bolt tie can be increased even more. The advantage: The number of fastening points can be reduced. Therefore, the BZ3 additionally offers a new variety of fastening options that weren't possible before.

The anchoring depth of the BZ3 can be varied continuously. This way, the setting depth can be adjusted exactly to the individual requirements and the respective installation situation. The setting of the bolt tie with a minimal setting depth reduces the amount of both the drilling and the setting work required as well as the danger of hitting reinforcements.

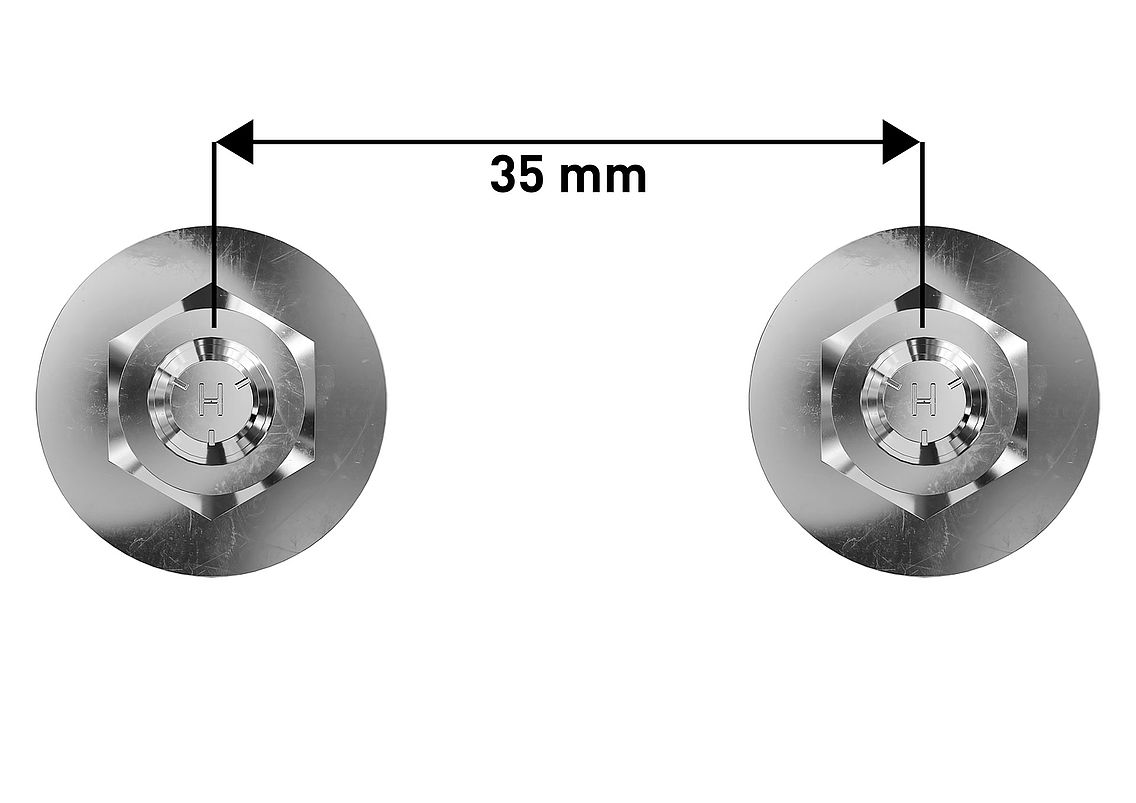

An innovative calculation method means small spacings

The innovative calculation method, which forms the basis for the use of the BZ3, makes it possible to allow for the smallest centre and edge distances, depending on the concrete thickness and anchoring depth. In this way, the BZ3 from the OBO portfolio can already be used from a centre distance of 35 mm and an edge distance of 40 mm.

An unbeatable combination

The very high approved tensile and transverse loads of the bolt tie BZ3 – together with the maximum anchoring depths – provide many advantages for mounting, such as smaller plates, smaller anchor dimensions and significantly larger support spacings.

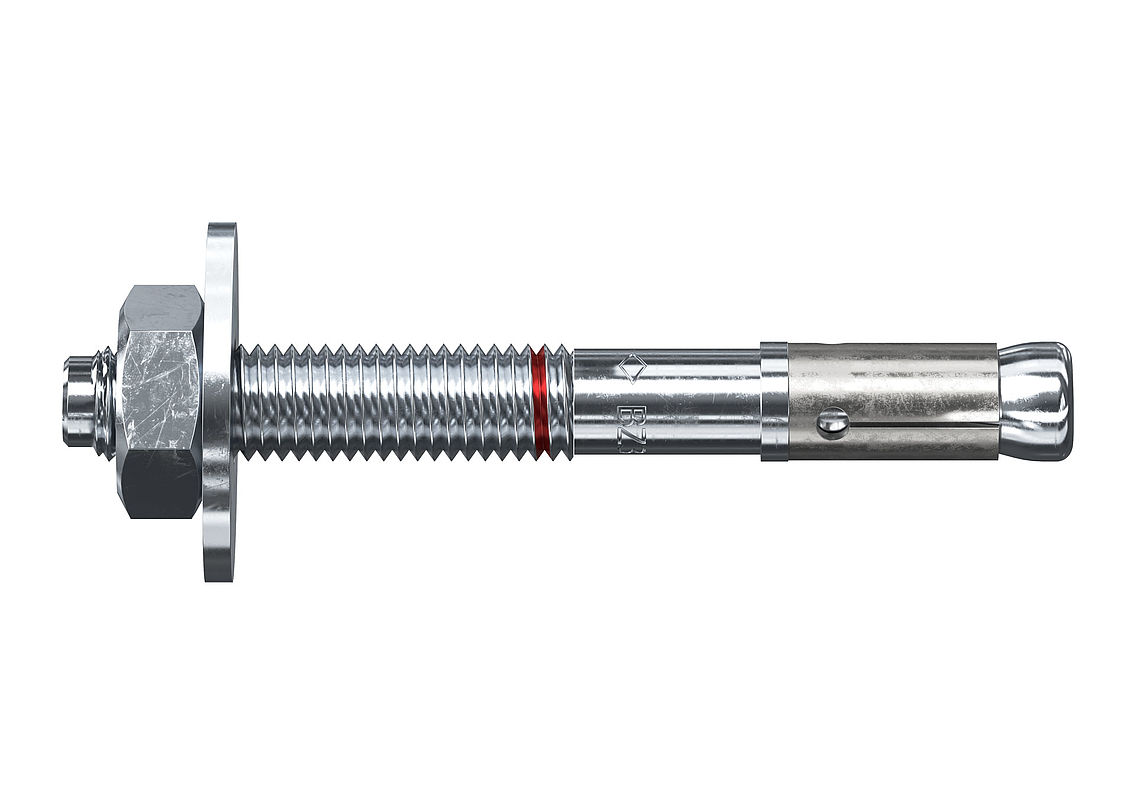

Thought-out down to the last detail

- A long thread: Which means it can be used flexibly for both small as well as large clamping ranges or for off-set mounting.

- An expansion clip that grips immediately: In order to achieve the tightening torque, significantly fewer turns are needed. The time for mounting is therefore shortened.

- Red colour marking: Indicates at the pre-installation whether the bolt tie BZ3 has already been driven in to the minimum anchoring depth. This provides a higher level of mounting safety.

- Extra-short version: Good value and quickly installed.